It is a quality management system It sets out the requirements for quality management system. It helps businesses and organization to be more efficient and improve customer satisfaction. ISO 9001 is built on seven quality management principles.

read more

It is Environment Management System that sets out the requirements for the same. It helps organizations to improve their environmental performance through more efficient use of resources and reduction of waste, gaining a competitive advantage and trust of stakeholders.

Occupational Health and Safety Management System that prevents fatalities, injuries and ill health, there are many other benefits. The management system helps in identifying the opportunities to improve Occupational Health and Safety management along with improved Occupational health and safety performance.

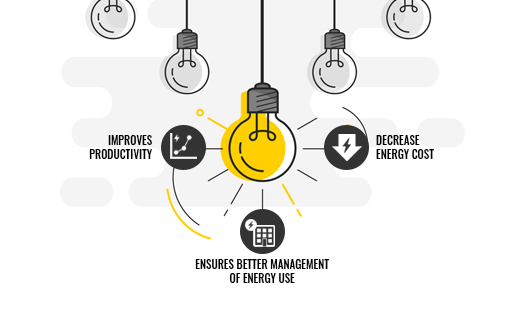

Energy Management System is critical to the organizations but often represents a significant cost – both to them and to the environment. It helps organizations better manage their energy use, thus improving productivity and decrease energy cost.

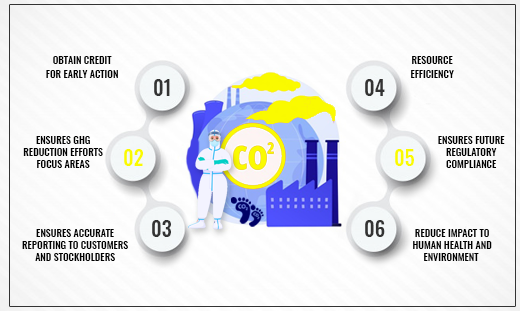

The standard provides governments, businesses, regions and other organizations with a complementary set of tools for programs to quantify, monitor, report and verify greenhouse gas emissions.

read more

The standard is published in three parts:

The standard enables organizations to put in place a Food Safety management system that helps them improve their overall performance when it comes to food safety. The potential benefits of having standard includes to consistently provide food related products and services that are safe along with improved management of risks.

Quality management for Medical devices benefits the organizations involved in any part of a medical device in increasing the safety as well as performance. It manages risk effectively, improve processes and efficiencies and gain a competitive advantage. It also demonstrates compliance and regulatory and legal requirements.

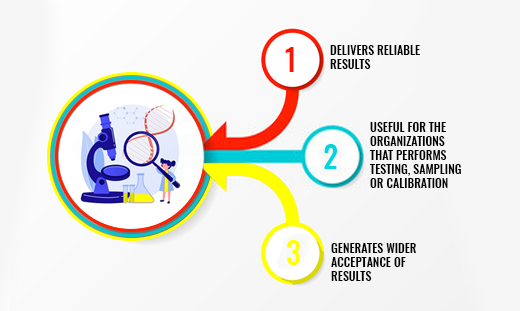

The standard is for competence of testing and calibration laboratories to deliver reliable results. It is useful for the organizations that performs testing, sampling or calibration. It helps in facilitating cooperation between laboratories and other bodies by generating wider acceptance of results.

The standard benefits organizations by assisting in contributing to sustainable development. It intends to encourage organizations to achieve beyond legal compliance. It helps organizations by providing appropriate guidance concerning social responsibility and can be used as part of public policy activities.

Anti-bribery management system intends to install an anti-bribery culture within an organization and implement appropriate controls which ultimately increase the chance of detecting bribery and reduce its incidence in first place. It covers bribery in the public, private and not-for-profit sectors, including bribery by and against an organization or its staff, and bribes paid or received through or by a third party.

The Educational Management System is applicable to any organization that uses a curriculum to support the development of competence through teaching, learning or research, regardless of the type, size or method of delivery. It aims to enhance satisfaction of learners, other beneficiaries and staff through the effective application of its Educational organizations management systems.

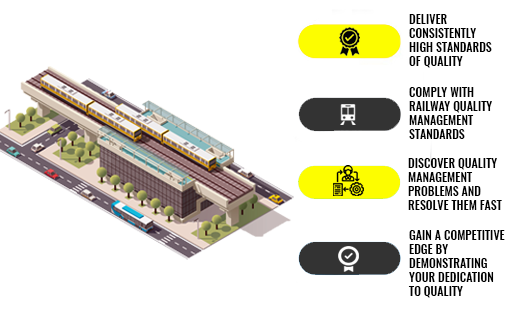

It is global standard for quality management systems in the rail industry. It is based on the ISO 9001 quality management standard, with the addition of rail-specific requirements.

Auditing standard for management system helps organizations achieve their objectives. In order to the best out of a management system and ensure continuous improvement, regular auditing needs to take place. Not an easy task if, like most organizations, you have several management systems in place. Guidelines for auditing management systems offers a uniform, harmonized approach, enabling effective auditing across multiple systems at the same time.

Sterilization of Health care products – Radiation specifies requirements for the development, validation and routine control of a radiation sterilization process for medical devices. It specifies requirements for designating a medical device as sterile along with requirements for sterilization of used or reprocessed devices.

Information Security Management System specifies requirements for establishing, implementing, maintaining and continually improving an information security system within the context of the organization. It ensures that the requirements for the assessment and treatment of information security risks tailored to the needs of the organization are addressed.

Quality requirements for fusion welding of metallic materials provides the quality requirements for welded product. It encourages a proactive process-oriented approach to managing and controlling welding product quality in a workshop or on site. It is specially developed to identify all factors that could affect the quality of welded product that needs to be controlled at all stages, before, during and after welding.

Service Management System specifies requirements for an organization to establish, implement, maintain and continually improve a service management system. The standard includes the planning, design, transition, delivery and improvement of services to meet the service requirements and deliver value.

Medical laboratories – requirements for quality and competence standard can be used by medical laboratories in developing their quality management systems and assessing their own competence. It can also be used for confirming or recognizing the competence of medical laboratories by laboratory customers, regulating authorities and accreditation bodies.

The international standard for social accountability confirms your compliance with labor rights and serves a pillar of your demonstrable commitment to established social standards of corporate governance. It improves supplier relations, ensures transparency and confidence and gains explicit competitive advantages.

The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste. There are five steps in the system, each starting with the letter S: Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), Sustain (Shitsuke). By providing a systematic framework for organization and cleanliness, 5S helps facilities avoid lost productivity from delayed work or unplanned downtime.